Industry 4.0

solutions

In manufacturing, there’s lots of upsides to gathering and analyzing IoT data from your processes: less downtime, lower maintenance costs, longer machine lifetime, consistent quality, and more.

It’s the downsides you want to avoid: big upfront costs and steep learning curves in making sense of the data. At Dexmen, we have successfully tackled these issues.

Turning data into valuable information

We can gather data from various kinds of assets: direct machine data with no external sensors; wireless or wired sensor data from rotating machines; production data from other digital sources and systems, as well as status data from facilities and equipment via wireless sensors.

A secure cloud service receives the data from all sources and performs necessary data analytics, allowing you to monitor the performance of your assets with easy-to-use visual tools in real-time.

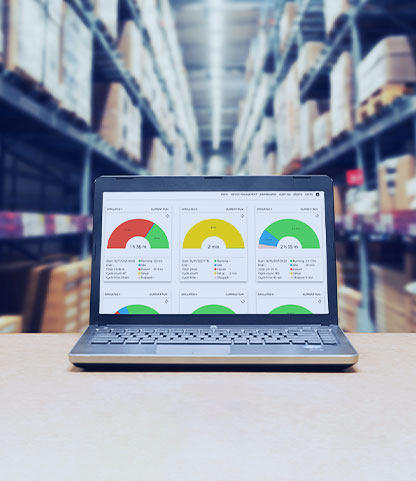

dexmen iot monitor

The easy-to-use, low-cost solution for condition monitoring and predictive maintenance.

- Simple to set up with various wireless sensors

- Simple to use: dashboard on your web browser

- Simple to maintain: data stored safely in the cloud

- Simple to tailor to your specific needs

1

Condition monitoring

To ensure uninterrupted production and consistent quality, monitor critical factors such as vibration-related variables gauging the condition of your machinery, or room temperature, air humidity, air quality, and air pressure. All in real-time.

2

Predictive maintenance

Save costs by performing maintenance only when and where it’s truly necessary. Detect failures before they occur through FFT analysis – a powerful tool for recognizing any deviations from the normal vibration patterns of rotating machines. FFT data allows you to pinpoint the source of the problem and predict when it might become critical.

3

Production monitoring

Streamline your production processes by observing your machine performance and utilization rate. Connect any machine to the system to find bottlenecks in real-time and make adjustments to optimize performance.

About us

We are a dedicated team of experts in digital data management and cloud-based solutions – and we started out on a mission.

All too often Industrial IoT projects rely on outdated technologies that require tons of time-consuming programming work, costing the customer lots of money. Our mission was to create the simplest, most easy-to-use, and most cost-effective solution for condition monitoring and predictive maintenance. And frankly, we believe we have succeeded in this mission.

Won’t take our word for it? See what our customers have to say: